DSC Pump (R) FGD Series

Capacity: 1083-2722L / s

Head: 26-27m

Speed: 550-740r / min

Material: Chrome alloy and rubber

Detailed Description

Hebei Delin Machinery is one of the largest pump company specialized in manufacturing slurry pumps in China, with land area of over 40,000m2 and construction area of over 22,000m2. The products are mainly used for the course of the river diversion, mining, metallurgy, urban planning, energy, coal, FGD, petroleum, chemical industry, construction material production, etc. DSC (R) The pump FGD series is a type of centrifugal pump, single suction, single-stage and horizontal structure, with benefits of wide flow, high efficiency and energy saving. FGD pumps series are compact in design and space saving. As a professional slurry pump manufacturer and supplier in China, we have developed a variety of materials for DSC pumps Series (R) FGD.

Features of FGD Pump

1. CFD flow simulation analysis technology is adopted to the pump wetted parts with reliable design and high efficiency.2. Adjust bearing assembly can change the position of the impeller spiral, keeping pump unit in an operating state of high efficiency.

3. DSC (R) pumps FGD series are rear side disassembly design, have a simple structure and are easy to maintain. There is no need to disassemble the suction and discharge tubes.

4. Double-row tapered roller bearings are mounted on one end of the pump, roller bearing at one end of the unit. Bearings are lubricated with oil, improving their working condition and prolong the life.

5. The mechanical seal is specially designed for cartridge mechanical seal used in the FGD pump process DSC (R) series FGD pumps with reliable operation.

Material for DSC Pump (R) FGD Series

We have developed a new type of material - duplex stainless white iron phase - which is especially suitable for FGD devices. With anti-abrasive properties of duplex stainless steel and corrosion resistance of chrome high iron, the material qualifies for the FGD process.

1. Pump body, pump and adapter plate cover are bearing pressure parts that are made of cast iron and coated with rubber.

2. The impeller, suction cover / insert liner front are made of stainless white iron duplex phase.

3. liner front, back lining, back insert liner are made of natural rubber which has anti-corrosive properties good, light weight and low cost.

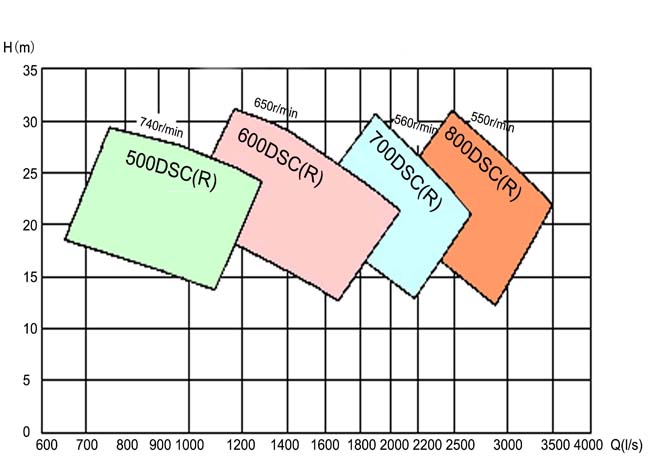

Selection Chart

Patameter performative

| Kind | Capcity (Q) | Head (H) | Speed (n) | Η Efficiency | NPSH | Discharge Day. / Suction diameter. |

| m3 / h | L / s | m | R / min. | % | m | (Mm / mm) |

| 500DSC (R) | 3900 | 1083 | 26 | 740 | 85 | 5 | 500/500 |

| 600DSC (R) | 6300 | 1750 | 26 | 650 | 88 | 4.1 | 600/700 |

| 700DSC (R) | 7600 | 2111 | 27 | 560 | 87 | 4.3 | 700/800 |

| 800DSC (R) | 9800 | 2722 | 27 | 550 | 90 | 5.2 | 800/900 |

Dimension installation

| Kind | AN | BB | B | D | E1 | E2 | F * | h1 | h2 | J | K | M * | L1 | L2 | d | Weight (kg) |

| 500DSC (R) | 1773 | 1000/960 | 850 | 652 | 110 | 51 | 595 | 35 | 40 | 120 | 210 | 421 | 150 | 400 | f42 / f40 | 4000 |

| 600DSC (R) | 1855 | 960 | 850 | 670 | 110 | 50 | 667 | 35 | 40 | 120 | 284 | 525 | 330 | 610 | F39 | 4580 |

| 700DSC (R) | 2315 | 1300 | 1100 | 895 | 130 | 75 | 768 | 40 | 45 | 150 | 355 | 583 | 375 | 720 | f51 | 7280 |

| 800DSC (R) | 2460 | 1300 | 1100 | 885 | 135 | 75 | 933 | 40 | 45 | 150 | 355 | 712 | 550 | 800 | f51 | 8300 |

| Kind | N | P1 | P2 | Q * | T1 * | T2 * | U1 | U2 | DO2 | ED2 | n2 | d2 | DPC2 | DO1 | DI1 | n1 | d1 | DPC1 |

| 500DSC (R) | 580 | 950 | 500 | 665 | 60 | 44 | 735 | 946 | 715 | 500 | 20 | 33 | 650 | 715 | 500 | 18 | 33 | 350 |

| 600DSC (R) | 700 | 1050 | 500 | 775 | 48 | 40 | 901 | 1155 | 910 | 600 | 24 | 30 | 840 | 840 | 600 | 18 | 36 | 770 |

| 700DSC (R) | 780 | 1290 | 700 | 930 | 68 | 60 | 1080 | 1350 | 1025 | 768 | 24 | 40 | 950 | 1025 | 700 | 22 | 40 | 950 |

| 800DSC (R) | 930 | 1400 | 700 | 985 | 62 | 62 | 1141 | 1493 | 1125 | 900 | 28 | 40 | 1050 | 1125 | 800 | 26 | 40 | 1050 |